If you’re in manufacturing, construction, or metalworking, you’ve likely heard the term “roll forming machine.” But what exactly is it, and why is it revolutionizing high-volume metal production? Let’s break it down.

A roll forming machine (or roll former) is a specialized piece of industrial equipment that continuously bends long strips of metal (coils or sheets) into consistent, complex cross-sectional profiles using a series of rotating rollers. Unlike stamping or press braking, roll forming is a gradual, incremental process, shaping metal without cutting or welding.

How Does a Roll Forming Machine Work?

-

Material Loading: A metal coil (steel, aluminum, copper, etc.) is fed into the machine.

-

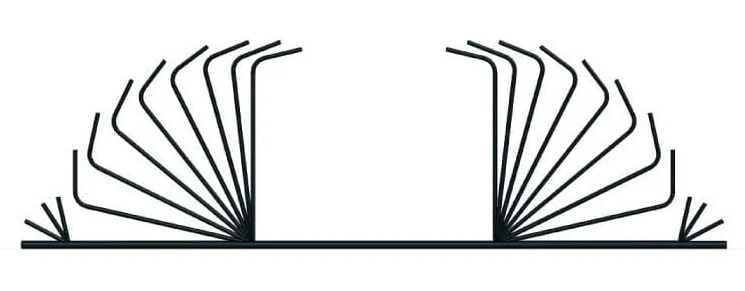

Progressive Forming: The strip passes through multiple sets of precision-engineered rollers (stages).

-

Each roller station bends the metal slightly further toward the final shape.

-

-

Cutting: Once fully formed, the profile is cut to length (flying cutoff saws, shears, or lasers).

-

Output: Finished parts exit the system – ready for assembly or packaging.