TEST

METAL PERFORATION LINE

RACK SYSTEM MACHINES

Metal Ceilings Solution

Search By Industries

c/u/z Roll FormING MACHINE

Roll forming machine for car componets

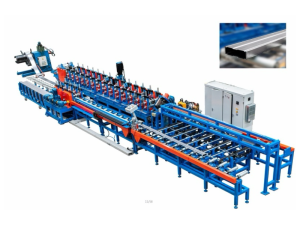

Pipe Making machine

FEATURED MACHINES

-

Metal Floor Deck Roll Forming Machine

-

Carrier Roll Forming Machine

-

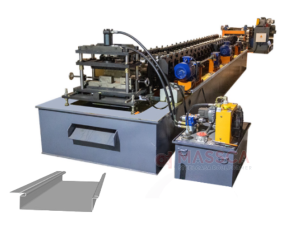

Metal Stud and Track Roll Forming Machine

-

Metal Perforated Machine Coil to Coil Line

-

Perforated Bead Roll Forming Machine for Plaster Gypsum Board Protection and Expansion

-

Metal Coil Perforation Line Cut to Length Machine

-

Ceiling Cross T Grid Roll Forming Machine

-

Ceiling Main T Grid Roll Forming Machine

-

Linear Strip Ceiling Roll Forming Machine

-

600X600mm Metal Ceiling Tiles Full Automatic Making Machine MSTD-600

-

U300 Baffle Ceiling Roll Forming Machine

-

Baffle Ceiling Roll Forming Machine U200 Compact Design

-

High Speed Grilyato Open Cell Ceiling Production Line

-

U10/15 Open Cell Ceiling Making Machine

-

Carrier Roll Forming Machine

-

U Shape Baffle Ceiling Roll Forming Machine U25/20000*30/200

-

Scaffolding Board Production Line

-

Cable Tray Ladder Making Machine

-

Stud and Track Roll forming machine

-

38 Main Carrying Channel Roll Forming Machine – Light Gauge Steel Profile Production for ceilings

-

Hydrualic Oil Press for Metal Ceiling Tile Production

-

Shelf Panel Roll Forming Machine

-

Metal Wall Panel Roll Forming Machine

-

Metal Floor Deck Roll Forming Machine

How to Choose the Right Transmission Method for Roll Forming Machines?

November 3, 2025

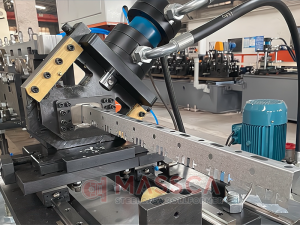

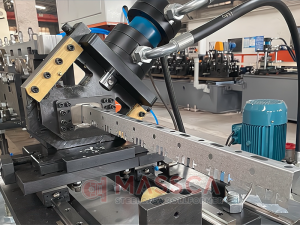

Three main roll forming machine driven method How to choose right method for your machine? Transmission Method Application Scenarios Transmission Precision Maintenance Cost Transmission

Principle of Precision Fixed-Length Positioning

August 27, 2025

The precision fixed-length cutting relies on a “pre-signal + precise positioning” mechanism, which ensures the cut length of profiles matches the target dimension exactly. Here’s

Electrical Basics of Cold roll forming machine

August 21, 2025

The electrical system is what makes a cold roll forming machine tick—it’s got parts like PLCs, HMIs, encoders, and more, all working together to shape