Description

I. Description of Metal Wall Panel Machine

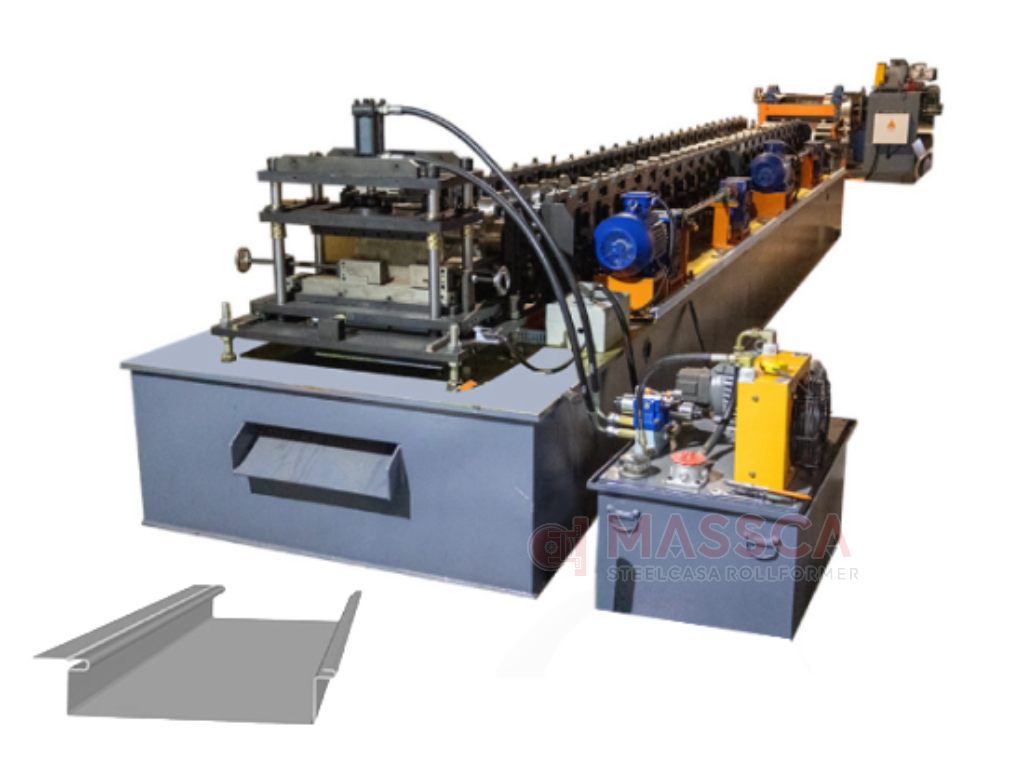

A wall panel forming machine is a specialized piece of equipment designed for the manufacturing of metal wall panels. It is a crucial asset in the construction and manufacturing industries, enabling the efficient production of high-quality wall panels.

II. Main Specification of the wall panel machine:

| Hydraulic decoiler | 5 Ton |

| Inner diameter of the coil | 480-520mm |

| outer diameter | 1250mm |

| Forming speed | 0-12m/min |

| Machine frame base | Weld by 36 # H Steel |

| Shaft material | 45# steel |

| Shaft diameter | 70mm |

| Roller material | 45# steel |

| Motor | 5.5 KW |

| Hydraulic power | 3 KW |

III. Working Process of the Massca Metal Wall Panel Machine:

Hydraulic Decoiler → High precision straightener→ Corner Shearing Machine → Roll Forming Machine → Fix-length Cutting → Discharge Table

IV. Feature of the wall panel machine:

Reviews

There are no reviews yet.