Description

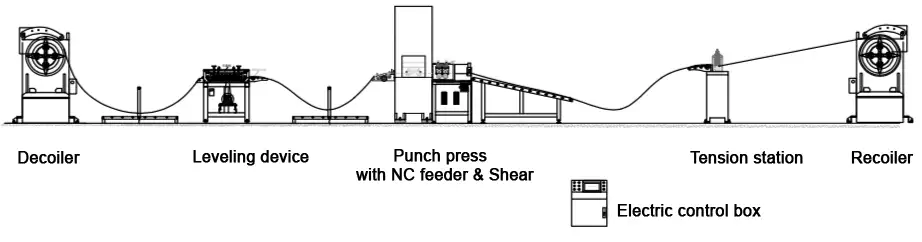

The MASSCA Metal Coil Perforation Line is an integrated system comprising an uncoiler with a built-in leveling, a punching unit, a length-cutting shear, and a recoiler (optional). These components operate in seamless coordination to efficiently produce both perforated coils and perforated sheet panels.

Whole process flow and details of the metal perforation line coil to coil machine:

Process flow of the coil to coil perforation line:

Details of each component of Massca sheet metal perforation line:

Hydraulic decoiler & Leveling device

315 Ton punch press ( for 1250mm width material , also can choose 160ton or 225ton punch press)

NC Feeder with electric shear ( can used as cut to length line)

Tension station and recoiler device

Each part plays a vital role in the production process: the uncoiler with a leveling ensures the metal coil is smoothly fed into the line while eliminating any material warping; the punch executes precise perforation according to preset specifications; the length-cutting shear trims the perforated material to the required dimensions; and the rewinder neatly collects the finished perforated coils. Together, they form a continuous and automated workflow that guarantees consistent quality in manufacturing perforated metal products.

Reviews

There are no reviews yet.