Description

The metal floor deck roll forming machine is a cornerstone of modern steel construction, combining efficiency, precision, and flexibility to meet the growing demand for lightweight, durable, and cost-effective floor systems.

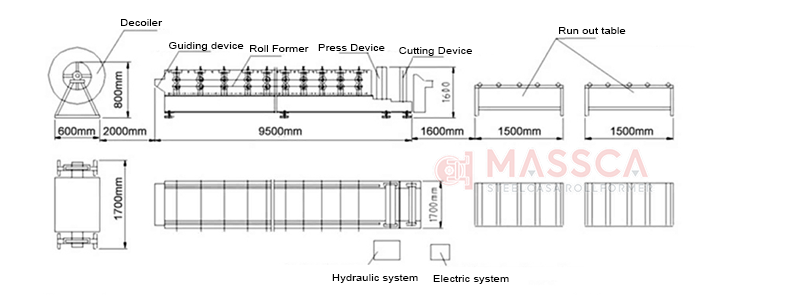

The production process of the metal floor deck roll forming machine follows a streamlined, continuous workflow:

- Decoiler (Uncoiler): Holds and feeds the metal coil into the system, with tension control to prevent coil slippage or deformation during unrolling.

- Leveling Unit: Corrects flatness defects in the uncoiled metal sheet, ensuring the material enters the forming stage with a smooth, uniform surface—critical for consistent roll forming.

- Roll Forming Station: consisting of multiple groups of precision-engineered steel rollers. Each roller group applies incremental bending force to the metal sheet, gradually shaping it into the desired cross-sectional profile of the floor deck (e.g., ribbed, corrugated, or trough-shaped).

- Cutting System: Trims the continuously formed metal deck into fixed-length panels after the forming process. Common cutting methods include hydraulic shearing .

- PLC Control System: A programmable logic controller that automates the entire process—regulating feed speed, roll pressure, cutting length, and production counts. It also includes a human-machine interface (HMI) for operators to set parameters, monitor operations, and troubleshoot errors.

- Run-Out Table/Stacker: Conveys the finished floor deck panels to a collection area and stacks them neatly, reducing manual handling and ensuring safe storage.

2. Working Principle

- Coil Loading: A metal coil (e.g., 0.8–3.0mm thick galvanized steel) is mounted on the decoiler.

- Uncoiling & Leveling: The decoiler feeds the coil into the leveling unit, where rollers flatten the metal sheet to eliminate internal stresses.

- Gradual Forming: The flattened sheet enters the roll forming station, where each set of rolls bends it by a small angle (typically 5–15° per station). After passing through all roll pairs, the sheet takes on the permanent cross-section of the floor deck.

- Precision Cutting: Once the formed deck reaches the preset length (set via the PLC), the cutting system activates to separate the panel from the continuous strip.

- Finished Product Handling: The cut floor deck panels are transported to the run-out table and stacked automatically, ready for packaging or on-site use.

3. Key Advantages

- High Automation: Minimal manual intervention reduces labor costs and human error, enabling 24/7 continuous production.

- Superior Precision: Incremental cold forming ensures consistent panel dimensions (tolerance ±0.5mm) and uniform rib height/width, meeting strict building code requirements.

- Efficiency: Production speeds range from 10–30 meters per minute (depending on material thickness and profile complexity), far faster than traditional stamping or welding methods.

- Flexibility: Quick-change roll sets allow the machine to produce different floor deck profiles (e.g., composite floor decks, non-composite floor decks) by replacing only the forming rolls, adapting to diverse project needs.

- Material Savings: Cold forming minimizes material waste (typically <2%) compared to cutting-based processes, and the finished panels’ ribbed structure enhances load-bearing capacity without increasing material thickness.

4. Applications

Metal floor deck panels produced by this machine are essential in the construction industry, primarily used as:

- Permanent Formwork: For cast-in-place concrete floors in steel-framed buildings (e.g., industrial workshops, warehouses, shopping malls). The metal deck supports the concrete during pouring and curing, eliminating the need for temporary wooden formwork.

- Structural Reinforcement: Composite floor decks (with shear studs welded to the panel surface) bond with concrete to create a composite slab, enhancing the floor’s load-bearing capacity and spanning ability.

- Roofing/Cladding Auxiliaries: In some cases, the machine can be reconfigured to produce similar profiles for roof decks or wall cladding, expanding its utility.

Common end-users include prefabricated building manufacturers, steel structure contractors, and construction companies focused on high-rise buildings, industrial facilities, or modular construction.

Reviews

There are no reviews yet.