Description

Linear Strip Ceiling Roll Forming Machine

MASSCA Metal Linear Strip Ceiling Making Machines offer full solutions for cold-rolled linear/S/U-type ceiling strips. Adjustable via touch screen, support custom sizes & high-end edge bending.

Main Specifications:

- Material: Color steel coil or aluminum coil

- Material thickness: 0.4-0.6mm

- Profile width: 85-300mm (per drawings or samples)

- Profile height: 15mm (per drawings or samples)

- Dimensional specifications: Per drawings or samples

- Length tolerance: ±1.0mm

- Profile after cutting: Slight burrs, minimal deformation at the cutting edges

Working process flow of the linear strip ceiling machine:

Decoiler → Leveling device →Roll forming main machine→ fixed length cut-off- Run-out table

- Maximum coil width: 200mm

- Coil inner diameter: Ø460-Ø520 mm

- Maximum coil outer diameter: Ø1300 mm

- Maximum load capacity: 2000 kg

- Control type: Manual control – manual expansion

- Forming direction: Left to right

- Forming rollers: 16 passes (CNC multi-specification adjustment)

- Roller material: Gr12MOV steel

- Heat treatment hardness: HRC58-60°

- Roller surface treatment: Heat treatment + hard chrome plating

- Main shaft: Ø42mm, CR40 steel, quenched and tempered, precision turning and grinding;

- Frame structure: Plate-type frame [Note: Original “mm” lacks specific value, retained as is];

- Main bearings: 6207, domestic famous brand HRB;

- Motor power: 5.5 KW, Siemens or equivalent brand

- Forming speed: 45 m/min, flying shear

- Cooling device: 40W water pump;

- 3mm scrap cutting: 1 set

- Cutting material: GR12MOV steel

- Heat treatment hardness: HRC 62-65

- Hydraulic motor: 4.0 KW

- Cutting process: Servo system continuously cuts

- Servo motor: 1.3 KW

- Table length: 4 meters

- Structure: Square tube welded structure;

- [Note: Original item 3 is blank, retained as is]

- 7-inch touch screen: Delta (Taiwan, China)

- Speed controller: Delta (Taiwan, China) inverter

- Main electronic components: Schneider / SHILIN / joint-venture brands

- Length control: Omron encoder

- Electrical control panel: Sealed with a ventilation cooler

- Control power supply: Overload protection

- Electrical control cabinet: Equipped with aviation connector plugs

- Servo motor: 1.3KW (VMmore)

- Power supply: 380V, 50Hz, 3 Phases

- Width adjustment motor: 0.75KW, equipped with RV63 reducer

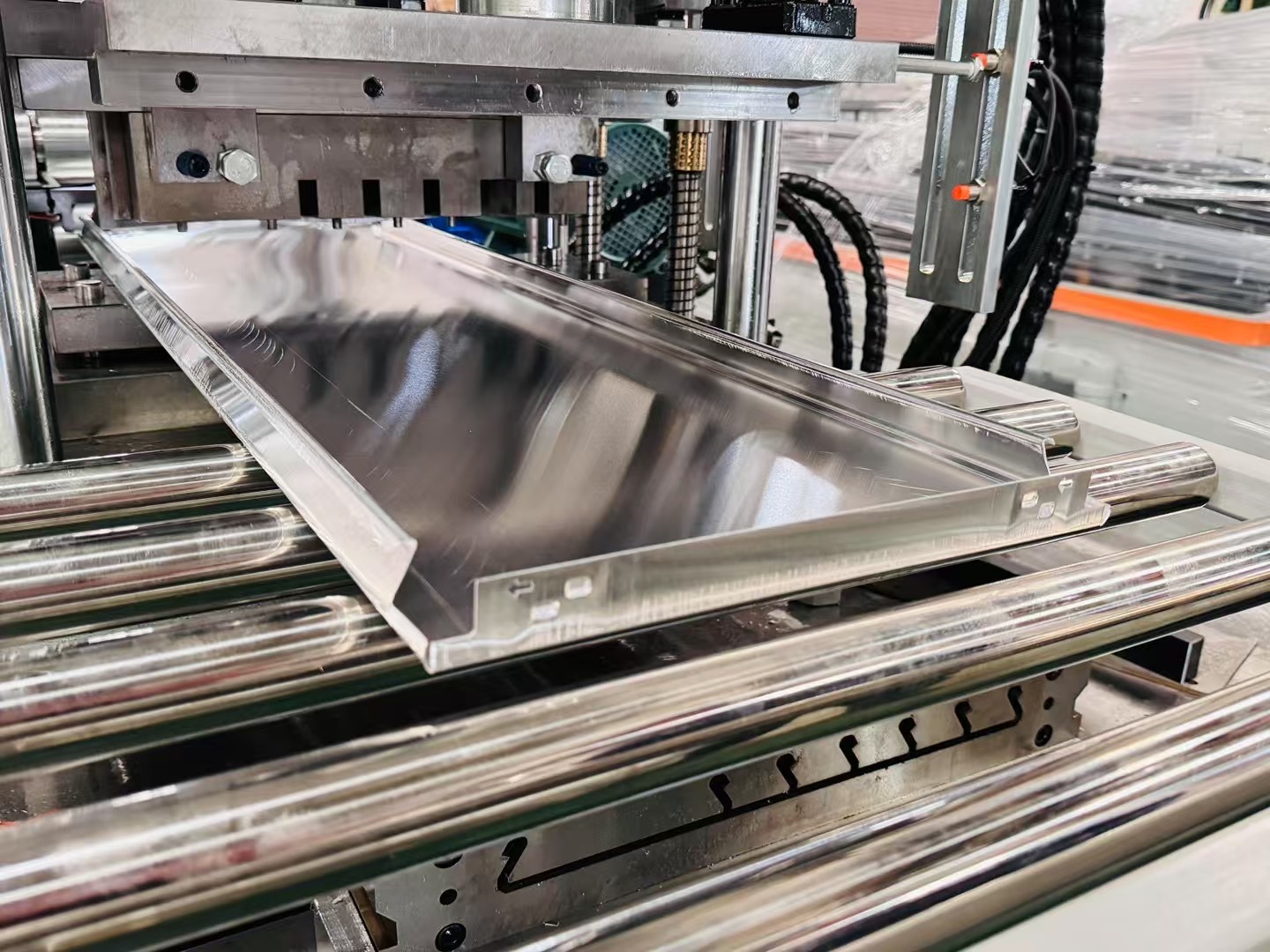

Linear strip ceiling profiles picture collection

Reviews

There are no reviews yet.