Description

Baffle Ceiling Roll Forming Machine U25/200*35/200

This production line mainly uses aluminum sheets and strips as raw materials, undergoing processes such as uncoiling, leveling, continuous roll forming (cold bending), and fixed-length cutting.

The cross-sectional height and width of the products can be infinitely adjusted, enabling the production of products with any dimensions within the designed range (bottom width: 25-200mm, flange height: 35-200mm).The width and height specifications of the products are adjusted via NC system. Operators only need to simply input the product’s width, height, and length on the touch screen, and all other actions of the production line will be completed automatically, with specification changes achievable within a few minutes.

The production speed can be adjusted freely within the specified range, making the entire line a cold bending processing equipment that realizes continuous and automated production

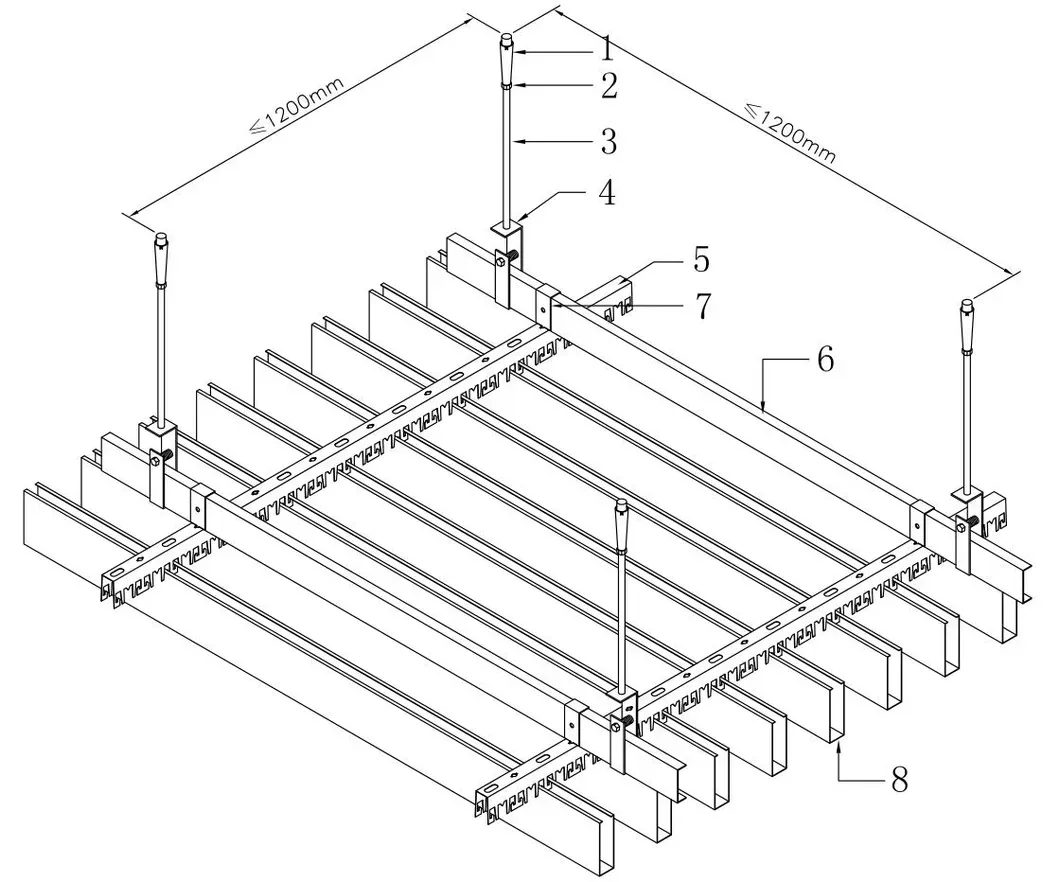

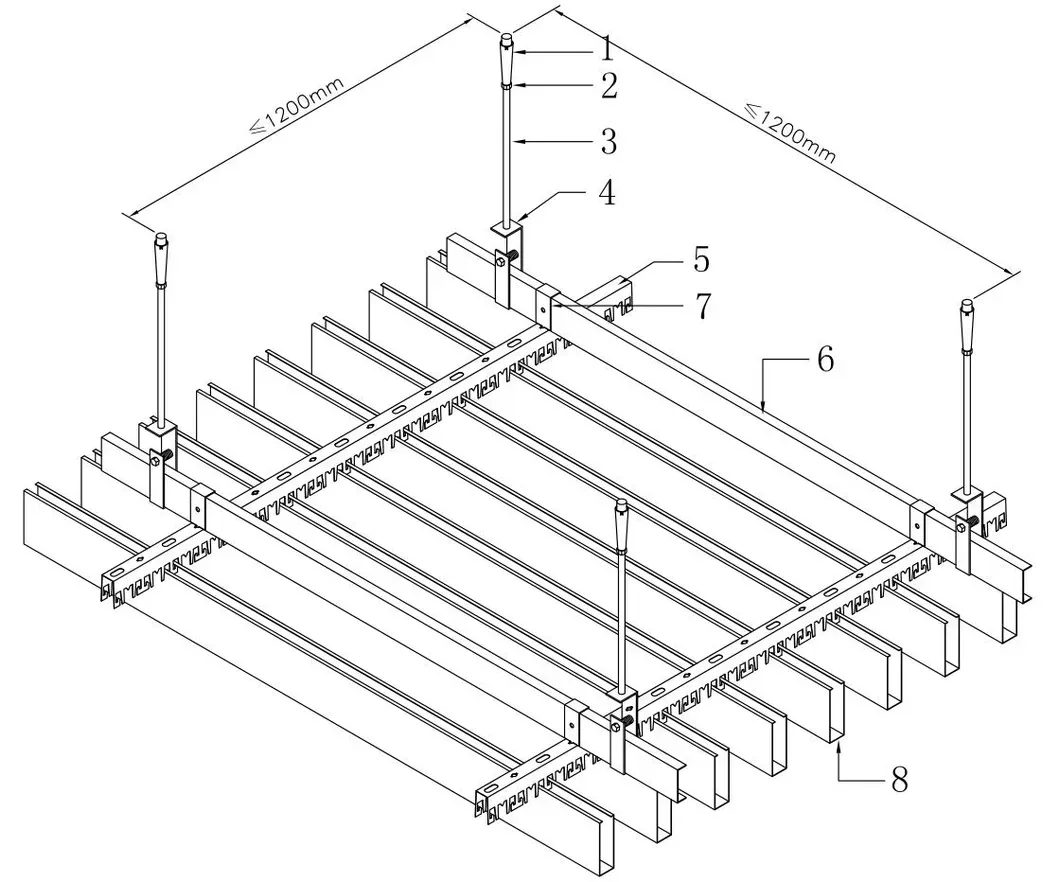

Baffle Ceiling Profile Drawing and detail:

- Bottom width: 25-200mm (CNC universal adjustment)

- Side height: 30-200mm (CNC universal adjustment)

- Thickness:

- Aluminum: 0.5-1.2mm (no gap adjustment required); manual gap adjustment is needed for thickness over 1.2mm

- GI (Galvanized Iron) and color steel: 0.4-0.7mm

Main Specification of the baffle ceiling making machine:

- Material: Aluminum / GI

- Material thickness: Aluminum: 0.5-1.2mm, GI/ PPGI: 0.4-0.7mm

- Feeding material width: 520mm

- Forming speed: 0-50m/min

- Power supply: 415v, 50hz, 3ph

- Motor power: 20.8kw

- U Shape Baffle Ceiling Size: bottom width: 25-200mm, flange height: 30-200mm

- Ball screw CNC width-adjustable structure

- Groups of rollers: 16 groups of rollers

- Control: PLC Control

- Transmission by Gearbox

Work Process of the Baffle Ceiling Roll Forming Machine:

Decoiler→Auxiliary roller & Feed Guide device→ Roll forming main machine → Straightener→ Hydraulic following cut-off system → Run-out table

Details of each component of the U-shaped Baffle ceiling roll forming machine:

Decoiler

- Manual expansion and tight

- Loading capacity: 5 ton

Roll Forming main machine

Machine Frame:

- Adopts an integral structure. The workbench steel plate is 10mm thick, and the entire frame is welded with 8mm steel plates.

- The gantry undergoes precision machining.

Precision Cating Stand Side Plates:

With a thickness of 40mm, they are processed by CNC. The surface is treated with spray coating

Forming Rollers:

- Material: 45# steel

- Roller Driving Diameter Standard: Φ98mm

- After heat treatment to reach HRC 53, they undergo precision machining. The surface is further treated with hard chrome plating and polishing.

- Groups of forming rollers: 16 groups

Transmission Mechanism:

- Main Shaft material: 40Cr;

- Shaft diameter: Φ70mm. It is finished by precision grinding after machining and heat treatment (quenching and tempering).

- Shaft bearings: Harbin Grade G8 bearings.

- Equipped with a Shanghai three-phase AC motor, a Changzhou cycloidal pinwheel reducer, and chain wheel transmission.

Width-adjusting Component:

- The width-adjusting components support the entire left and right stands via 25mm linear square rails

Cutting Device

- Uses a hydraulic cutting frame. The bottom sliding part is equipped with SBR precision linear sliding units and supporting guide rails

Electric control system:

- The production line adopts multiple servo motors for chasing and cutting. The width and height can be adjusted numerically.

- Width adjustment: AC 0.75KW*2

- Height adjustment: AC 0.2KW*4

- Tracking shear motor: AC Servo 1.5kw

APPLICATIONS

Reviews

There are no reviews yet.