Description

Metal punching equipment is widely used in decorative wall panels, curtain walls, ceilings and other fields. Various designs can be achieved by changing molds. The complete set of equipment mainly consists of an uncoiler, a leveling line, a servo feeder, a high-precision punch press, and a shearing device. Subsequent processes are completed by a press brake or an oil press. Punch presses of different tonnages are selected according to different material thicknesses and sheet sizes. The core of this production line lies in the selection of punch presses and the manufacturing of molds.

Due to the high-intensity stamping actions required by the punching line, the precision of the molds is extremely demanding; otherwise, needle breakage and inaccurate step distance may occur.

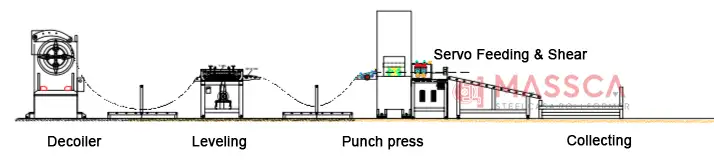

Layout of the metal perforation cut to length line:

Details of each component of the Massca sheet metal perforation line:

-Hydraulic decoiler & Leveling device

5 Ton with loading torri

-315 Ton punch press ( for 1250mm width material, also can choose 160ton or 225ton punch press)

-NC Feeder with electric shear ( can be used as cut to length line)

-Run-out table and collecting device

Each part plays a vital role in the production process: the uncoiler with a leveling ensures the metal coil is smoothly fed into the line while eliminating any material warping; the punch executes precise perforation according to preset specifications; the length-cutting shear trims the perforated material to the required dimensions; and the rewinder neatly collects the finished perforated coils. Together, they form a continuous and automated workflow that guarantees consistent quality in manufacturing perforated metal products.

Reviews

There are no reviews yet.