Description

Shuttle Rack System is a high-density storage solution composed of racks, shuttle carts, and forklifts. This highly efficient storage method significantly improves warehouse space utilization, offering customers a revolutionary storage alternative!

Compared to drive-in racks, it provides equivalent storage capacity while being more secure and durable with reduced risk of rack damage. The system operates with shuttle carts that run on rechargeable batteries along specially designed rail tunnels. Equipped with lifting platforms and positioning sensors, each pallet can be transported to the farthest storage position within the tunnel.

Both storage and retrieval operations are conveniently performed through remote-controlled forklift operations. The shuttle carts automatically lift pallets and travel along the rail-guided aisles, efficiently transporting goods either from the entrance to deep storage locations or vice versa.

Machine Photo:

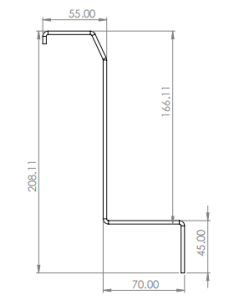

Shutter Rail Shapes:

Shutter Rack Rail Production Line Process Flow:

Decoiler → NC leveling device → Punch Press / Oil station → Material Feeding Guide → Roll Forming Main Machine → Hydraulic cut-off → Pneumatic Discharge

Main Components of the shutter rail equipment:

| 1 | Decoiler 3Ton/5Ton |

| 2 | Leveling |

| 3 | Punch Press with NC Servo Feeding |

| 4 | Guiding device |

| 5 | Roll Forming Main Machine |

| 6 | Straightening |

| 7 | Hydraulic Cut-off |

| 8 | Pneumatic discharge table 8m |

| 9 | Molds: Punch Die, Cutting blade |

Details of each component of the shutter rack rail machine:

- Decoiler : 5 ton hydarulic decoiler

- Leveling device: 9 rollers

- Material feeder: 4 roller feeder , roller material GCr15 steel

- Punch press: 125 ton Pneumatic clutch type

- Roll forming main machine:

- 22 group of rollers, 5 straigtening roller

- indepentand torri

- roller material: Cr12mov / GCr15 steel

- speed: 15m/min

6. Hydraulic cut-off: non-stop cut-off

7. Discharge table: Pneumatic discharge

Reviews

There are no reviews yet.