Description

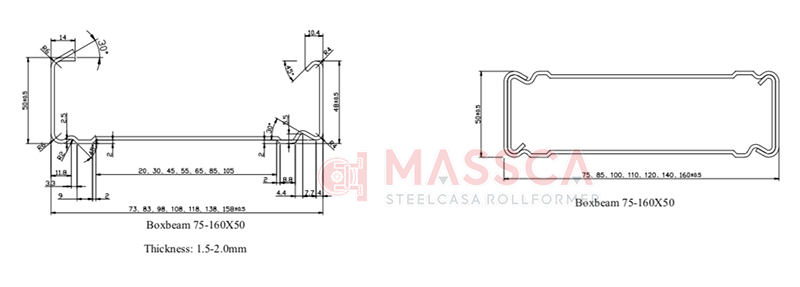

I. Profile drawing:

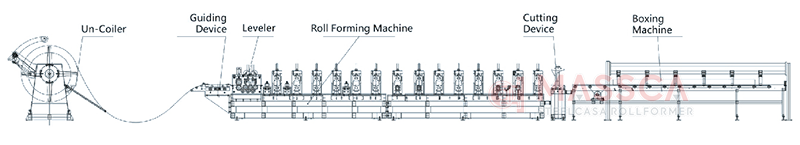

II. Process flow of the boxbeam roll forming machine

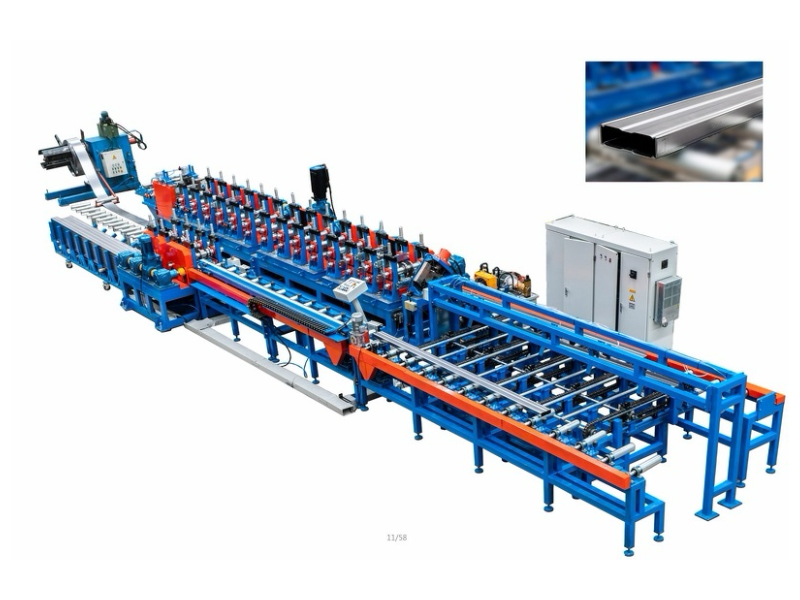

III. Main Components

i. Uncoiler

capacity: 3ton

ii. Roll forming main machine

- Number of forming stations: 18 groups

- Roller material: Cr12, HRC58-62

- Frame structure: 100 square tube, horizontally welded

- Integral clamping plate: 45# steel, 30mm thick

- Bearing specification: 62/63 series

- Transmission mode: Precision gears

- Drive motor: 11KW

- Reducer: WXD/silent series

- Straightening rollers: 1 set

- Changeover mode: Servo changeover

- Length fixing mode: Encoder

- Roller cooling mode: Independent emulsion water-cooled channel

- Equipment floor space (L×W×H): 22×1.5×1.2m

- Production speed: 5-10 meters/minute

iii. Flipping machine

- Process: Automatically flip the workpiece into the beam combining machine

- Flipping action: Fully automatic

- Clamps: One batch

- Action mode: Controlled by electric control system

- Length: 3 meters

- Speed: According to the rhythm of the forming machine

iv. Boxing machine

- Working property: Automatic clamping

- Forming clamping groups: 6 sets

- Power: 3KW

- Width adjustment mode: Servo full automatic

- Roller material: Cr12 finish-turned, HRC58-60

v. Hydraulic station

- Type: Horizontal

- Disassembly method: Quick-change structure

- Cooling method: Natural air cooling

- Punching frequency: 30 times/minute

- Oil tank capacity: Above 50L

- Power: 5.5KW

vi. Electric control system

- Function: Length/speed adjustable

- Inverter: Sine/Chinese famous brand

- PLC: XINJIE/Chinese famous brand

- Low-voltage electrical components: Chinese famous brand

- Encoder: OMRON/Japanese brand

- Optical fiber: Chinese famous brand

- Electrical cabinet fan: Chinese famous brand

Reviews

There are no reviews yet.