Description

U10/15 Open Cell Ceiling Making Machine

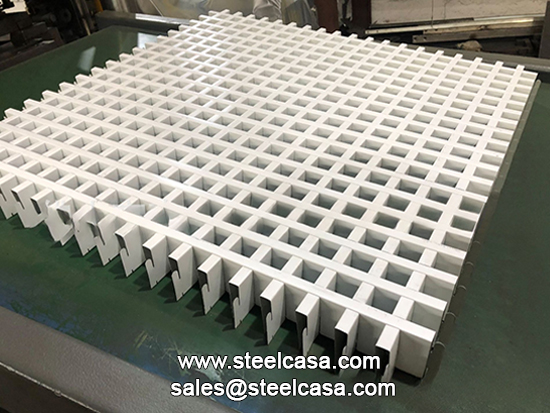

An open cell ceiling machine is a specialized roll-forming equipment designed to produce open-cell ceiling panels—lightweight, grid-like metal components widely used in modern interior decoration. These panels feature a distinctive open, lattice-like structure that combines aesthetic appeal with functional benefits like sound absorption, ventilation, and easy maintenance. The machine transforms metal coils (typically aluminum, galvanized steel, or stainless steel) into precisely shaped open cell profiles through a continuous cold roll forming process.

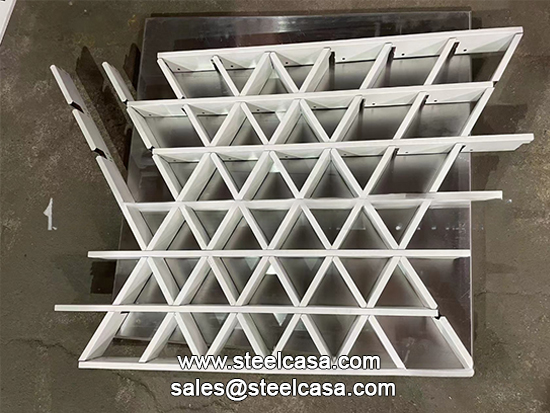

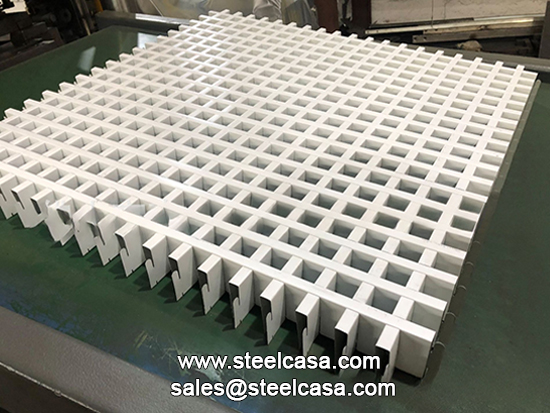

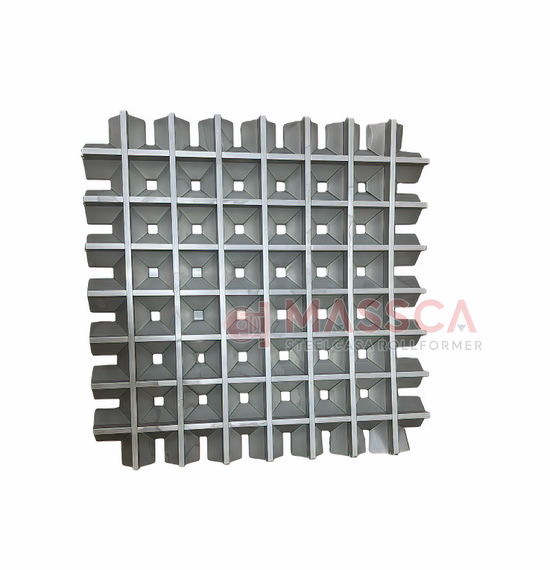

I. Profile Photos:

The commonly used grids in the current market include Triangular Grid, Pyramid Grid, and Classic Cube Grid.

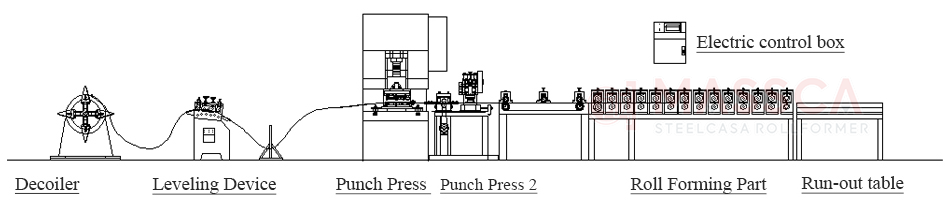

II. Working flow diagram:

III. Machine Component Parts:

Manual uncoiler → Leveling device → Punch device #1→ Punch device #2 → Roll forming part → Run-out table

IV. Main Parameters:

| 1 | Manual Uncoiler | Ø Loading capacity: 1ton

Ø No power, Manual expansion to tighten the coil |

| 2 | Leveling device | Ø 7 rollers / 9 rollers |

| 3 | Servo Feeder | Ø Servo motor: Yaskawa

Ø Feeding material thickness: 0.3-0.4mm |

| 4 | Power press 16ton | Ø Punching die: 2 sets, for Main grid and cross grid

Ø Punching distance: 50/60/75/86/100/120/150/200mm Ø 120 strokes /min |

| 5 | Cutting press 2 ton | Ø Cut-off die 1 set

Ø 180 stokes /min |

| 6 | Conveyor | Ø Auto Conveying: speed adjustable |

| 7 | Roll Forming Machine | Ø Forming rollers: 14 stations, including straightening device

Ø Treatment for rollers: Quenched and hard chrome plating Ø Side wall thickness: 25mm Ø Main shaft: φ38mm Ø Transmission: gear and chain Ø Roll forming speed: 30m/min |

| 8 | Run-out table | Ø Length: 3m |

| 9 | Electric Control System | Ø PLC: Panasonic, Japan

Ø HMI: Weinview, Taiwan Ø Servo motor: Yaskawa, Japan Ø Power supply: 380V,50Hz, 3PHS |

V. Machine photos for your reference

vi. Application of open cell ceilings:

Reviews

There are no reviews yet.