TEST

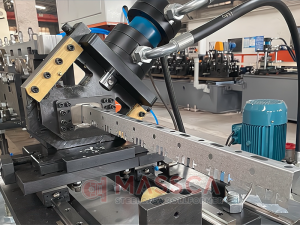

METAL PERFORATION LINE

RACK SYSTEM MACHINES

Metal Ceilings Solution

Search By Industries

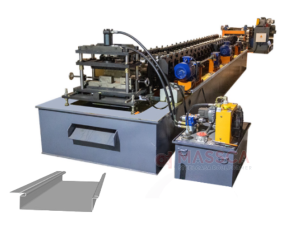

c/u/z Roll FormING MACHINE

Roll forming machine for car componets

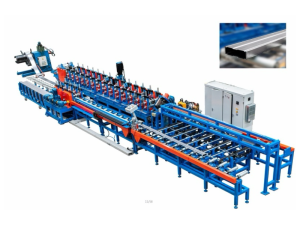

Pipe Making machine

FEATURED MACHINES

-

Metal Floor Deck Roll Forming Machine

-

Carrier Roll Forming Machine

-

Metal Stud and Track Roll Forming Machine

-

Metal Perforated Machine Coil to Coil Line

-

Perforated Bead Roll Forming Machine for Plaster Gypsum Board Protection and Expansion

-

Metal Coil Perforation Line Cut to Length Machine

-

L Wall Angle Roll Forming Machine

-

Ceiling Cross T Grid Roll Forming Machine

-

Linear Strip Ceiling Roll Forming Machine

-

600X600mm Metal Ceiling Tiles Full Automatic Making Machine MSTD-600

-

U300 Baffle Ceiling Roll Forming Machine

-

Baffle Ceiling Roll Forming Machine U200 Compact Design

-

High Speed Grilyato Open Cell Ceiling Production Line

-

U10/15 Open Cell Ceiling Making Machine

-

U Shape Baffle Ceiling Roll Forming Machine U25/20000*30/200

-

Ceiling Cross T Grid Roll Forming Machine

-

Scaffolding Board Production Line

-

Cable Tray Ladder Making Machine

-

Stud and Track Roll forming machine

-

38 Main Carrying Channel Roll Forming Machine – Light Gauge Steel Profile Production for ceilings

-

Hydrualic Oil Press for Metal Ceiling Tile Production

-

Shelf Panel Roll Forming Machine

-

Metal Wall Panel Roll Forming Machine

-

Metal Floor Deck Roll Forming Machine

The Role of Levelers/Flatting Machines in the Metal Stamping Sheet Field

August 20, 2025

In the metal stamping industry, metal sheets (such as carbon steel, stainless steel, or aluminum sheets) often suffer from defects like warping, curling, waves, or

Introduction to Shuttle Rack Systems

July 30, 2025

Shuttle rack systems are renowned for exceptional space efficiency. Compared to traditional heavy-duty racks, they increase warehouse space utilization to over 80% through parallel rail designs that

Comprehensive Guide to Cold Roll Forming Machine Operation & Maintenance in Extreme Heat

July 24, 2025

Temperature Monitoring & Control Install Temperature Sensors: Deploy real-time temperature sensors on critical components (motors, hydraulic systems, drive shafts) to continuously monitor temperature fluctuations. Workspace Cooling: Activate